When you look at drone rotors to buy online you’ll notice they’re advertised according to several characteristics. The most common is length. Together with pitch, these two factors play an important role in generating lift for a copter drone.

This page covers:

- Lift

- Rotor Length

- Rotor Shape (Coefficient of Lift)

- Rotor Blade Width

- Two, Three, Four, and More Rotor Blades

- Rotor Materials Composition

- Rotor Noise

- Rotor Connection Points

- Clockwise (CW) and Counter-Clockwise (CCW)

Lift

For reference, and to get your thinking juices flowing, consider the equation that defines how much lift your copter drone is going to generate. Don’t worry, we’re not going to get too deep into math, but for those who are inclined this can be illustrative:

L= (1/2) * ρ * A * CL * V2

- L is lift. This is what we want to maximize

- ρ is air density. We don’t generally have control over this, so we’ll forget about this variable.

- A is rotor disk area. This is essentially rotor length.

- CL is the coefficient of lift. This essentially refers to rotor shape.

- V is the velocity of airflow over the rotor. In other words, rotor speed or RPM. This is more related to motors, so we won’t cover it here. But as you can see increasing RPM will exponentially increase the lift your rotors provide. All other variables affect lift linearly.

So of these variables, we can control the rotor length, rotor shape, and rotor speed.

Rotor Length

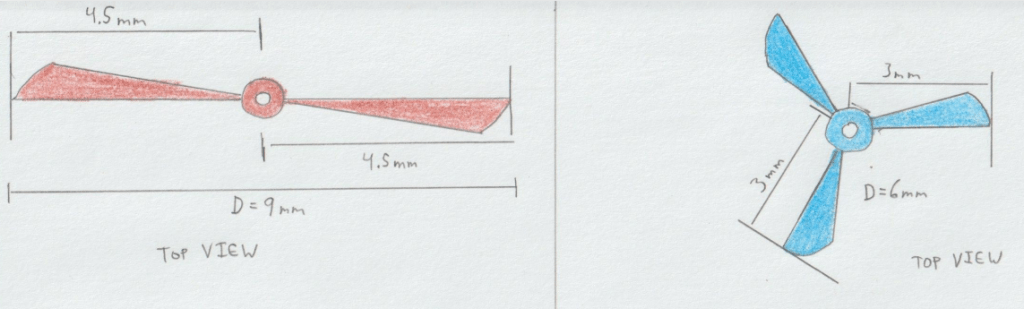

This is the most noticeable aspect of a drone rotor. And rotor length is another way of talking about the A variable for rotor disk area.

For the curious-minded, here is the equation for calculating rotor disk area:

A = π * (D/2)2

- A is the rotor disk area

- π is pi (3.14)

- D is rotor diameter

In other words, D is the length of the rotor from one end of the rotor blade to the other end of the rotor blade, passing through the center.

If you want to increase your rotor disk area, and therefore increase lift, you can do this by increasing the length of your rotors. Longer rotors mean more lift.

Note that having two, three, or four blades on your rotor doesn’t affect the rotor disk area, but changing those variables does affect the CL variable (the coefficient of lift).

Rotor Shape (Coefficient of Lift)

Think of a rotor’s shape on a helicopter, or an airplane propeller. It’s curvy and tapered. It isn’t a straight line with an abrupt pitch angle. Calculating the exact coefficient of lift for such a rotor involves variables like slopes and degrees; fluid dynamics and differential equations. These are too complex for our purposes here so we will disregard them.

Calculating the coefficient of lift also involves a variable we can definitely work with for simplified drone rotor modeling: angle of attack. This can be further simplified by referring to the pitch of the rotor blade.

Generally, an increase in pitch means an increase in the coefficient of lift, which means an increase in lift.

So the simple rule is that if you increase the pitch of your rotor blade you will get more lift.

An average rotor pitch is between 8 and 10 degrees. Low-pitch rotors range from 3 to 5 degrees. High-pitch rotors range from 10 to 15 degrees or more.

Like so many aspects of drone design, there is a cost-benefit analysis here. As you increase the pitch of your rotor it means your motor will have to be able to handle increased torque. And eventually as your pitch approaches 90 degrees you won’t get any lift.

For the curious, here is the full equation for calculating the coefficient of lift. Ignore it if it gives you a headache, but it doesn’t hurt to notice the linear relationship between CL and α:

CL = CL0 + Clα * α

- CL is the coefficient of lift

- CL0 is the coefficient of lift at zero angle of attack

- Clα is the change in lift coefficient per degree of angle of attack, or in other words, the slope of the lift curve

- α is the angle of attack (simplified to rotor pitch)

Rotor Blade Width

Increasing the width of your rotor blade increases the coefficient of lift by affecting the CL0 and Clα values. Mathematically those are too complex to delve into specifically here, so instead you can use the following general rules of thumb about rotor blade width:

- Increasing rotor width by 100% increases the coefficient of lift by 20%-30%

- Increasing rotor width by 50% increases the coefficient of lift by 10%-20%

- Increasing rotor width by 25% increases the coefficient of lift by 0%-10%

But this is a diminishing returns game. As your rotor blades get wider they are going to create more drag, require larger and more powerful motors, weigh more, and so on.

Rotor width is typically somewhere between a ratio of 5:1 and 10:1 (length:width). So if you had a 10-inch rotor (two blades that are five inches each), that rotor would be somewhere between one and two inches wide.

Two, Three, Four, and More Rotor Blades

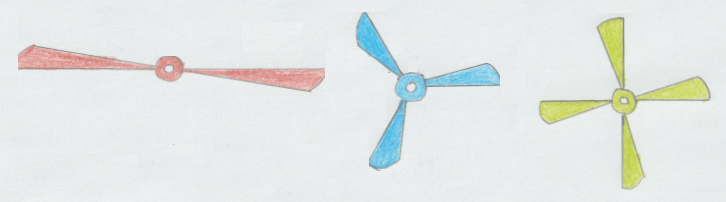

Most copter rotors are two blades, though it’s not uncommon to see rotors with three blades. Some rotors have four blades. Theoretically there’s no limit to the number of rotors you can have.

Increasing the number of blades on your rotor also increases its coefficient of lift. It does this by increasing the CL0 and Clα values. Since those are too messy to get into here, you can take a shortcut with the following general rules:

- Adding a third blade increases the coefficient of lift by 10%-15%

- Adding a fourth blade increases the coefficient of lift by 5%-10%

- Adding a fifth blade increases the coefficient of lift by 0%-5%

As with increasing the width of your rotors, adding additional blades nets diminishing returns. So if you’re really designing on the margins and you need to squeeze a bit more lift out of your drone, going with three blades instead of two could get you over the line. But if you really want to add lift power to your drone, modify variables like rotor length and pitch. And especially motor speed.

Rotor Materials Composition

Most consumer-level rotors you’ll see online are made from plastic. Expensive ones might be made from carbon fiber or composite materials like fiberglass and resin.

There are metal rotors and wood rotors but these aren’t so common for consumer copter drones. Wood generally breaks easier than plastic per unit of weight, and metal might take your finger off.

Rotor Noise

You’ll see some rotors marketed as having “low” or “reduced” noise. There are some things manufacturers can do to lower the decibels produced by drone rotors. The most obvious are to round or sweep the rotor blade tips.

Aside from these minor design changes, reducing rotor noise happens as a side-effect of buying more complex drones and expensive parts. But it’s rare these changes would be made for the express purpose of reducing sound:

- Harder or denser rotors made from more expensive materials like carbon fiber or composites will have reduced noise due to vibrating less

- Drones with more rotors, like a hexacopter, can more evenly distribute lift and therefore spin their motors slower, reducing noise. The same can be said for drones with longer rotors, and drones with wider rotors.

Rotor Connection Points

You’ll see drone rotors connecting to their rotor shafts in all kinds of designs:

- Center point connection

- Individual rotor blades connected to a spinning axis with a screw

- Self-tightening screw-on

- Quick release

- Mounting bracket with screws

There aren’t really any inherent advantages for one design over another. Every manufacturer tries to keep their weight down. The important thing is that rotors are attached securely and don’t vibrate or fly off their mount.

Clockwise (CW) and Counter-Clockwise (CCW)

It’s worth mentioning clockwise and counter-clockwise, which you’ll often see specified as CW and CCW, respectively. Some companies will specify these as “A” and “B” or “positive” and “negative”.

It’s important that your rotors spin in the correct direction so they provide lift, as opposed to driving your drone into the ground. Remember you want to balance your motors (torque) so that half of them are spinning their rotors clockwise, and half are spinning their rotors counter-clockwise.

Brushless motors can typically spin either direction depending on how you wire them, so that means when you buy rotors you need half that generate lift by spinning clockwise, and half that generate lift by spinning counter-clockwise. If you buy rotors that can be flipped over and used either way then you don’t need to worry if you’re using brushless motors.