You’ll encounter a ton of stats when browsing for brushless motors. If you’re putting a drone together it’s critical to understand several of these, and helpful to understand them all.

For starters, it’s critical:

- To know the “S” rating (voltage) that your motor is designed for, so you can make sure you have the right battery

- To know the max power usage (often expressed in amps) your drone motor requires at full-throttle, so you can make sure you have the right Electronic Speed Controller (ESC)

These two factors are the easiest to know: they’re typically stated directly up-front. And these are the two factors you must consider to do your basic homework when you’re choosing a motor that’s the right fit for your drone’s other critical components: battery and ESCs.

If too much jargon and a high learning curve are holding you back from getting hands-on, then read no further. If your drone is relatively lightweight and you nail down battery and ESC compatibility then you could be flying before you know it.

But if you want to fine-tune your motors even further there are more details to consider, and these will get you closer to a realistic assessment for whether your drone’s motors will be powerful enough to achieve lift-off.

These additional factors affect the power dynamics of your motor and its ability to fly:

- Motor KV rating

- Motor lift value

- Motor torque value

- Torque VS RPM: Motor Stator Specifications

- Torque VS RPM: Motor Resistance (mΩ)

- Torque VS RPM: Motor Slots and Poles

You’ll also see motor weight and shaft size as features often advertised. While these don’t directly relate to vital motor specifications, they are common and worth considering.

Motor Battery’s “S” Rating

This single specification should always be clearly stated for any motor. It refers to the battery “S” rating voltage that your motor is designed for, anywhere between 3.7 volts (1S) to 22.2 volts (6S).

Voltage directly affects how fast a motor spins, and this directly affects how much lift it can generate.

Don’t go connecting your motor directly to your battery (that’s what ESCs are for). Just know that motors are specifically advertised for specific voltages. Motors will often be compatible with a range of battery voltages. For example, it will specify its compatibility with 2S-4S batteries.

Make sure that your motor is designed for the battery voltage (“S” value) you’re using.

Motor Max Power Usage (Amps)

Motors are often advertised by their max amps value, but not always. If you’re lucky, they will be.

If there’s a single amp value listed for your motor, it likely refers to the peak/burst current your motor uses. This is how much current your motor draws from the battery at full-throttle, for around 10 seconds. For less powerful motors this is typically somewhere around 12 amps. For more powerful motors this is typically somewhere around 40 amps.

Knowing this value in amps allows you to calculate how many amps your ESC needs to be. And this in turn is critical for calculating the “C” value you need in a battery.

Motors may also be advertised by amperage values that supplement max ratings. Sometimes next to a “burst/peak current” amps value you may see a “continuous current draw” amperage value. This is extra information, with “continuous current draw” referring to how many amps your drone’s motor uses when it’s not working to its full potential; idling, hovering, or patrolling. Typically “continuous current draw” amp ratings are around half of what they are for burst/peak full-throttle current demands.

While it’s convenient when all statistics are expressed in amps, sometimes motor power usage may be expressed in watts or horsepower. For these you’ll just need to do the math, which requires factoring in your battery’s voltage (“S” value).

Here are the conversions:

- Watts: Watts = Current * Voltage

- If your motor’s max power usage is advertised at 921 watts with a 6S battery (22.2 volts), then its max amps rating is 31.5 amps (921 watts / 22.2 volts)

- Horsepower: 1 HP = 756 watts

- If your motor’s max power usage is 1 HP with a 6S battery (22.2 volts), then it is 756 watts, or 34.1 amps (756 watts / 22.2 volts) (*this is for mechanical/imperial HP used in the USA)

When it comes to expressing power usage, a drone motor should definitely express a value. For the sake of convenience this would be in amps, but if not, then in watts or horsepower. Without any of these be weary, because you won’t be able to properly determine how many amps your ESC needs to be rated for, nor the “C” value (capacitance) of your battery.

It’s common for drone motors to express their grams of thrust rating, newtons rating, and/or KV rating, but none of these can be used to determine a motor’s power usage rating (typically expressed in amps). However, these factors are relevant for considering related aspects of a motor’s power.

Are Your Motors Powerful Enough to Achieve Lift-Off?

In some ways answering this question is easy. Take the total weight of your drone, and compare this with the total combined lift power of your engines. If your engines create more lift than your drone weighs, then you’ll have flight.

Of course, it’s more complicated than that. This is where rotor design for copter drones becomes relevant. And several of these design features relate to motor specifications.

If you read that page on rotor design, you’ll notice that as motor RPMs increase linearly, the lift-power of an engine increases exponentially. This highlights the advantage of relatively high values for drone motor RPMs, expressed as a KV rating.

And while KV ratings are often an advertised feature of motors, another commonly advertised value for motors is their lift value. This is literally how many grams of thrust a motor can generate. If your drone weighs 800 grams, and you have four motors that can each generate 250 grams of thrust (1,000 grams total or 1 kg), then you’re going to be flying.

Motor KV Rating

A motor’s KV rating refers to how many rotations per minute (RPMs) a motor will spin, per volt applied, with no load.

In this case a “load” refers to a rotor, so the KV rating refers to the motor’s neutral spin without any extra torque or resistance.

“Per volt applied” means for each additional volt, the motor will spin an additional KV value. So for example, a motor that’s rated at 1960 KV means:

- With a 1-volt power source it will spin 1,960 RPM

- With a 2-volt power source it will spin 3,920 RPM

- With a 3-volt power source it will spin 5,880 RPM

- With a 4-volt power source it will spin 7,840 RPM

Factor in the “S” value (voltage) of your battery and you can calculate how many RPMs your motor will achieve with no load, based on its KV rating.

Motor Lift Value

Some drone motors state outright their lift value. This is often expressed in grams of thrust, but you may also see this expressed in Newtons of thrust.

For example, a motor rated for 1,500 grams of thrust (1.5 kg of thrust) could single-handedly fly a drone that weighed 1,400 grams.

In case your motor’s thrust is expressed in Newtons, this is the conversion factor:

- 1 Newton = 102 grams of thrust

So your 1,500-grams-of-thrust motor is equivalent to a motor that provides 14.7 Newtons of thrust (1,500 g / 102 N = 14.7 N).

When motors provide their lift values, consider these as ballpark estimates. There’s actually much more than just brute motor force that goes into calculating a drone’s lifting power. See this section for more details on what goes in to calculating lift.

But generally speaking, for a motor to generate more lift, it must be able to withstand higher levels of torque.

Motor Torque Value

Doing any of the following will increase lift, and also increase the torque (energy demands) on a motor:

- Spinning faster (higher RPMs)

- Having longer rotors

- Having rotors with a higher pitch angle

- Having more rotor blades (for example, three instead of two)

- Having wider rotor blades

You’ll notice that aside from RPMs, all these values that increase lift but also add to motor torque are related to rotor design. Essentially: motors are designed for specific types of rotors.

Added torque from a rotor is translated into increased usage of power by the rotors (added amps). Some rotors will specify their amp draw at full-throttle, which is very useful because you can compare this directly to your motor’s rated amperage.

But it’s all too common for rotors to mention nothing about their full-throttle amp draw. What’s much more common is for drone motor vendors to specify the length of the rotors they’re designed for. This is often specified directly in inches or centimeters.

Sometimes rotors are also listed with a combined diameter-pitch value. If you see a rotor that’s advertised as “1045” that means its diameter is 10 inches and it has a 4.5 degree pitch.

One of the easiest ways to over-torque your motor is to use rotors that are double or triple the length the motor is designed for. At minimum, over-torquing your motor will typically cause it to overheat. Significantly over-torquing a motor can cause it to melt, catch fire, or otherwise burn out. Rotors that are too long can also cause heavy mechanical wear like motor bearing failure or coil winding damage.

Torque VS RPM: Motor Stator Specifications

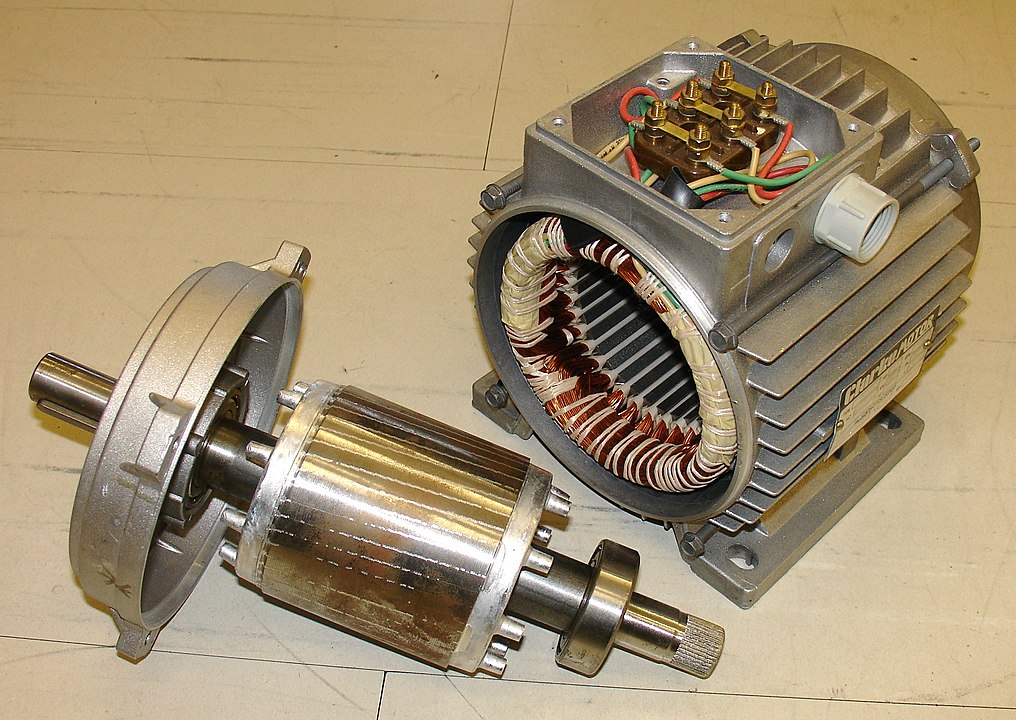

Brushless motors typically specify their stator size. The stator is the part of the brushless motor that’s attached to your drone’s body.

Disassembled brushless motor showing stator (right) and rotor (left). Dozens of slots/teeth are visible inside the stator, while alternating magnetic poles (contained underneath the shiny metal film) are less visible in the rotor.

This is how you’ll commonly see stator sizes expressed:

- 1806

- 2010

- 2212

- 2306

The first two numbers refer to the stator’s diameter in millimeters. The second two numbers refer to the stator’s height in millimeters.

A common average range for stator sizes is between 1806 and 2207, although at the extremes stators can range from 1104 to 2312.

A stator’s torque and RPM potential are determined by its diameter and height. Maximizing RPM will reduce torque, and maximizing torque will reduce RPM:

- Taller stators mean higher torque and lower RPM

- Shorter stators mean higher RPM and lower torque

- Wider diameter stators mean higher torque and lower RPM

- Thinner diameter stators mean higher RPM and lower torque

So if you want to maximize torque, your stator would be something like 2312. And if you want to maximize RPM potential, your stator would be something like 1104. Generally racing drones will maximize for RPM potential, while lifting drones will maximize for torque.

Torque VS RPM: Motor Resistance (mΩ)

Sometimes drone motors will also express their resistance value, typically in milli ohms (mΩ). If you use a multimeter to measure the resistance across two of the motor leads, this is will tell you the motor’s resistance.

- A relatively low resistance, like 50 mΩ, means the motor maximizes torque over RPMs

- A relatively high resistance, like 100 mΩ, means the motor maximizes RPMs over torque

Racing drones will have higher resistance values, while lifting drones will have lower resistance values.

Torque VS RPM: Motor Slots and Poles

It’s not uncommon to see drone motors advertised as follows using words like “configuration”, “framework”, or “slot pole”.

- Configuration: 9N12P

- Framework: 12N14P

- Slot pole: 14N16P

N refers to the “number” of stator slots in the motor’s winding. P refers to the alternating number of north-south magnet “poles” in the rotor. If you’re curious you can see these components in the picture above of the stator and rotor components of a brushless motor.

What’s important to know is that, once again, there’s a tradeoff between torque and RPM potential based on which of these values you select:

- If you want to maximize RPM (racing drones) then use lower N and P values, but these will decrease your motor’s torque capability

- If you want to maximize torque (lifting drones) then use higher N and P values, but these will decrease your motor’s RPM potential

- If you want to build a middle-road drone, go for mid-range N and P values

Typical motors will have NP values that range as follows:

- 7N8P (mini)

- 9N10P (racing)

- 10N12P (general)

- 12N14P (general)

- 14N16P (lifting)

Motor Weight and Shaft Size

Motor weights are typically expressed in grams. These are often overlooked, but on a drone everything boils down to weight. There can be notable variation in motor weight in units that otherwise have similar specifications.

Standard drone motors can typically weigh anywhere between 10 and 35 grams.

Motor shaft size and motor weight are two very common features you’re likely to see specified for a motor.

Shaft size is typically given for diameter in millimeters. Sometimes it’s given like this:

- M3 (shaft size is 3 mm in diameter)

- M4 (shaft size is 4 mm in diameter)

- M5 (shaft size is 5 mm in diameter)